商品の詳細

商品説明

【商品名】:テイクアップ TAKE-UP YGシトリン カーネリアン オパール ムーンストーン 茶金石 K18 ピアス ゴールド

【状 態】:

中古:B(使用感少な目/小キズ、ヨゴレ少々)

【状態説明】:

細かな擦れ等はございますが、目立った使用感はありません。撮影中の状況により、掲載写真と実物とで色合いの誤差が若干生じる場合がございます。 そのため微細な誤差を理由とする返品交換には対応致しかねますので予めご了承下さい。【中古:B(使用感少な目/小キズ、ヨゴレ少々)】

【商品コード】:

kyd-2401200010-je-036901782

【参考価格】:

-

【ジャンル】:

ピアス

【ブランド・モデル】:

テイクアップ

【商品説明】:

人気ブランド【テイクアップ】の【ピアス】が入荷致しました。一点物となりますので、この機会をお見逃しございませんようご検討くださいませ。 *バックヤードに保管している場合がございますので、店頭でお手に取りたいという場合にはお気軽にお問い合わせください。

【実寸サイズ】:

トップ部分チェーン長さ:約5cm ピアス針:約0.8cm

【メーカーサイズ】:

-

【お品物の素材】:

K18 YGシトリン カーネリアン オパール ムーンストーン 茶金石

【カラー】:

ゴールド

【状態】:

中古:B(使用感少な目/小キズ、ヨゴレ少々)

【配送料金】:

全国: 北海道: 沖縄:4,(一部地域を除く)

※離島のお客様は通常送料のほか、別途離島中継料金がかかります。

料金はお住まいの地域により変わるため別途ご案内申し上げます。

【その他 重要なご案内】:

出品店舗が同一の場合にのみ同梱を行う事ができます。ご了承下さい。

表示価格での販売となり、値下げ交渉などは承る事ができません。

店舗でも併売させて頂いているため、お品物が同時に売れているなど、ごくまれに商品をご用意できない場合がございます。

【展示店舗】:

オービタル経堂店

東京都世田谷区 経堂1-12-8(12:00~20:00)

店頭受取希望のお客様はオーダーフォームにてお申し付け下さい。

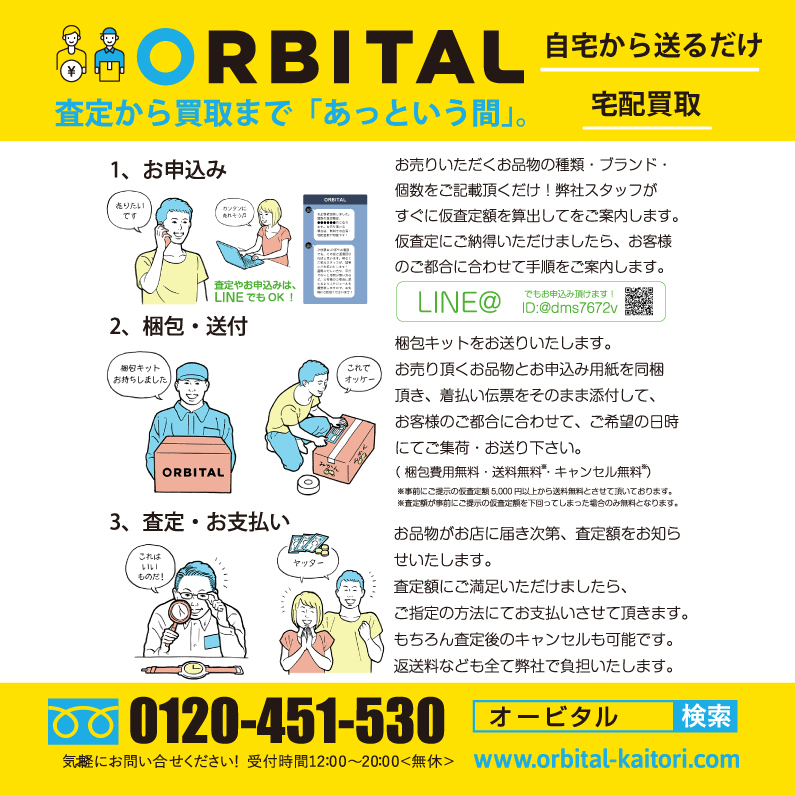

【買取案内】:即日出張買取と買取価格保証であんしん!便利!

オービタル経堂店では、アパレル・ファッション・衣類などを中心として、

食器、コスメ、お酒、アート、デジタル家電、など、ラライフスタイルカジュアルアイテムを何でもお取り扱い。

即日出張買取・楽速宅配買取にてご不要になられたアイテムを買取致します。

買取ご希望のお客様はオーダーフォームにてお申しつけ下さい。

お見積りだけでもOK。もちろん、お見積りは無料です!買取価格が先にわかるから安心。

しかも買取時は買取価格保証でさらに安心です。

【ご利用案内】:

ご不明な点はご質問欄にてお受付しております。お気軽にご連絡下さい。

※ストア情報ページにございますアドレス宛ではお受付できません。ご了承下さい。

ご購入・ご落札の後は、ストア用のオーダーフォームへのご入力をお願いしております。

取引ナビや連絡掲示板からのご連絡には対応しておりませんのでご了承下さい。

商品の説明

最新のクチコミ

ラズベリーボムとクラレットダズルを購入。

ラズベリーボムは凄く不思議な発色!つける角度によってグレー寄りになったりピンク寄りになったりして楽しいです。かといって派手になりすぎず馴染みやすいのでこの手のタイプの中では日常使いしやすいカラーです。個人的にデカ目にはしたくないので着色直径が裸眼と同じサイズなのも嬉しい。

クラレットダズルはパープルとグレーが合わさった綺麗なカラー!虹彩の模様が自然で高発色ながら浮きません。14.5ですが、感覚的には14ぐらいに感じられ、個人的には逆に良かったです。

付け心地は個人的に良いと感じました。

こちらの2色はまたリピートしようと思います!

- cef*****さん

- 44歳

- アトピー

- クチコミ投稿 4件

購入品

まずネット限定の色合いが可愛くて気に入っています。

家電量販店にも足を運んで、サイズ感や機能性を確認して購入を決めました。

見た目だけではなく、使用感と多様な機能性に満足です。

さすがアイリスオーヤマです。

- ebc*****さん

- 29歳

- アトピー

- クチコミ投稿 3件

購入品

幅が普通サイズのバスタオルの半分になってもデメリットはありません。長さはそのままなので小さいタオルという感じはしません。メリットはたくさんあって

1.家族がそれぞれ個別に使っても洗濯量はさほど増えない

2.干す時にコンパクト。パラソルハンガーで大丈夫

3.シャンプー後に髪を包むのに最適サイズ

4.吸水性がいい

5.くすみカラーがオシャレ

6.すみっこに縫い付けてあるタグがオシャレ

7.洗濯を重ねても風合いがかなりいい

8.これほど高機能な割りにお値段がメチャ高くない

この幅と長さと品質と値段が揃っているタオルってありそうで無いです!

スリムバスタオル本当に使いやすいです。

- bdf*****さん

- 48歳

- アトピー

- クチコミ投稿 2件

購入品

今回、4ヶ月になりSサイズでは小さくなってきたので、2枚目としてMサイズを購入。

1枚目の時もぐっすり6〜7時間寝てくれていましたが、Mサイズに変更しても変わらずよく寝てくれます。

もうネントレもばっちりで夜まとまって寝てくれるのでホントに効果絶大です!

- adc*****さん

- 31歳

- アトピー

- クチコミ投稿 1件

購入品