商品の詳細

商品説明

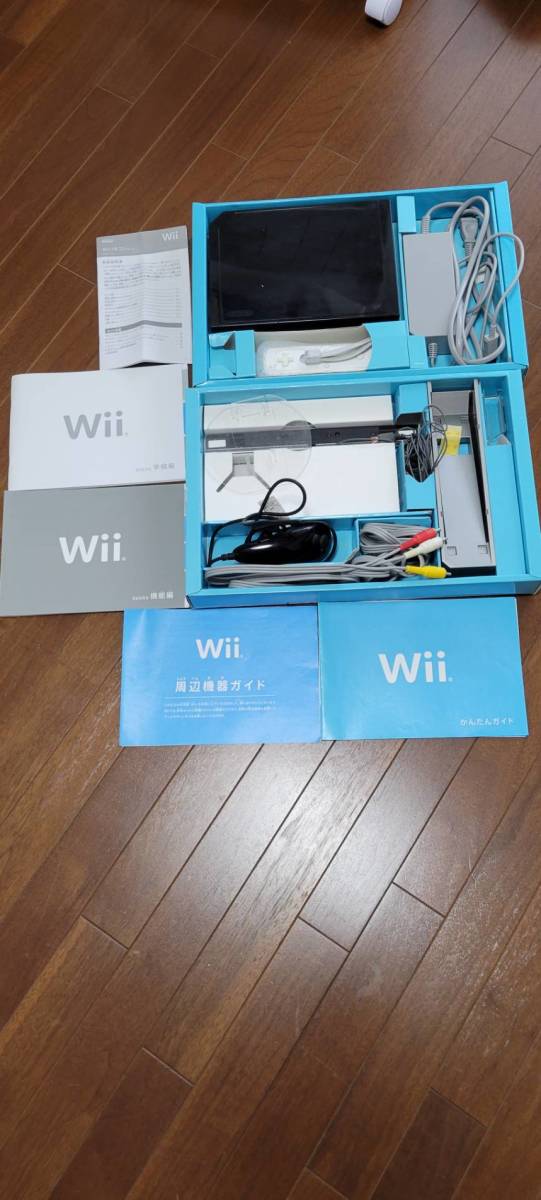

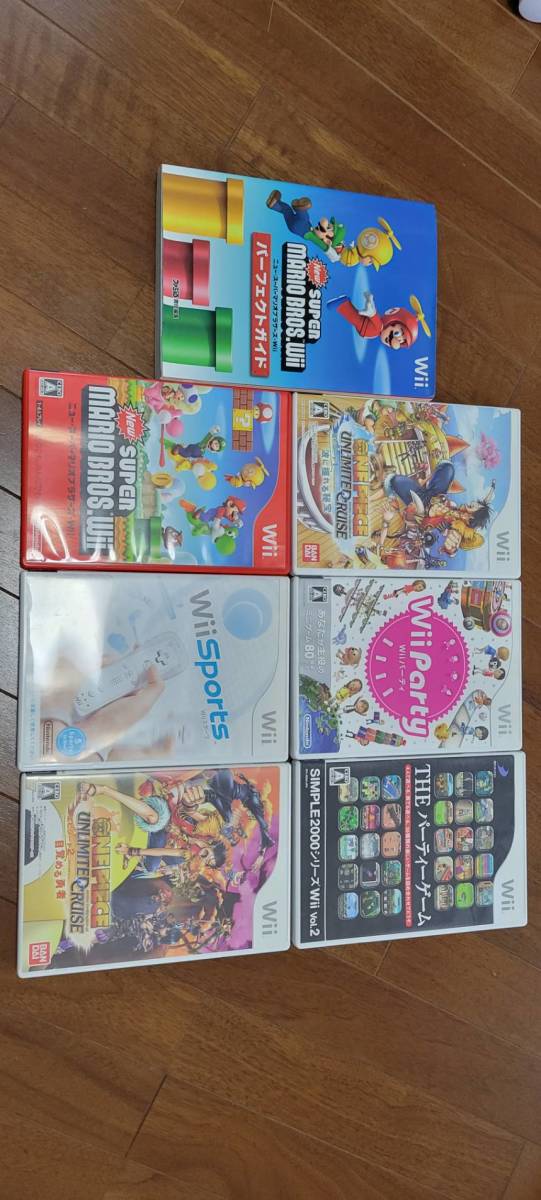

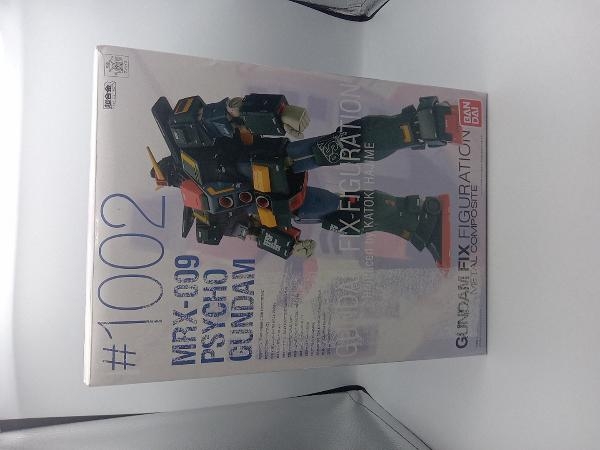

部屋の整理をしてきたら出てきました。まとめての出品になります。本体については,欠品があるかもしれません。※仮面ライダーのベルト、黄緑の箱と白色とオレンジの箱については、は出品対象外です。

お取引後は、ノークレーム・ノーリターンでお願いします。

商品の説明

最新のクチコミ

厚手で使いやすく、毎日のトイレ掃除に欠かせません。もう少し安い物で他社の製品を使った事があるのですが、わたしには香りが合いませんでした。

- cef*****さん

- 29歳

- アトピー

- クチコミ投稿 1件

購入品

シンプルで、良い感じです。

この値段で、この品質、満足です。

- ebc*****さん

- 23歳

- アトピー

- クチコミ投稿 3件

購入品

ネイビーを購入。しっかりした生地で高見えします。真夏には少し厚手の生地ですが、後ろのプリーツがふんわりしてるので暑くはないです。可愛くて大満足な商品です。

- cbe*****さん

- 48歳

- アトピー

- クチコミ投稿 3件

購入品

姪っ子の誕生日はシルバニアファミリーシリーズ!去年はウサギのお母さんと女の子だったので今年はお兄ちゃんがいるので男の子を購入!後お父さんも購入しました。後は赤ちゃん(^-^)も。

- dbf*****さん

- 28歳

- アトピー

- クチコミ投稿 1件

購入品

外のサイトより安くしてもらっていたんので購入しました

- eac*****さん

- 50歳

- アトピー

- クチコミ投稿 2件

購入品

おもちゃ、ゲームのデイリーランキング

-

-

2

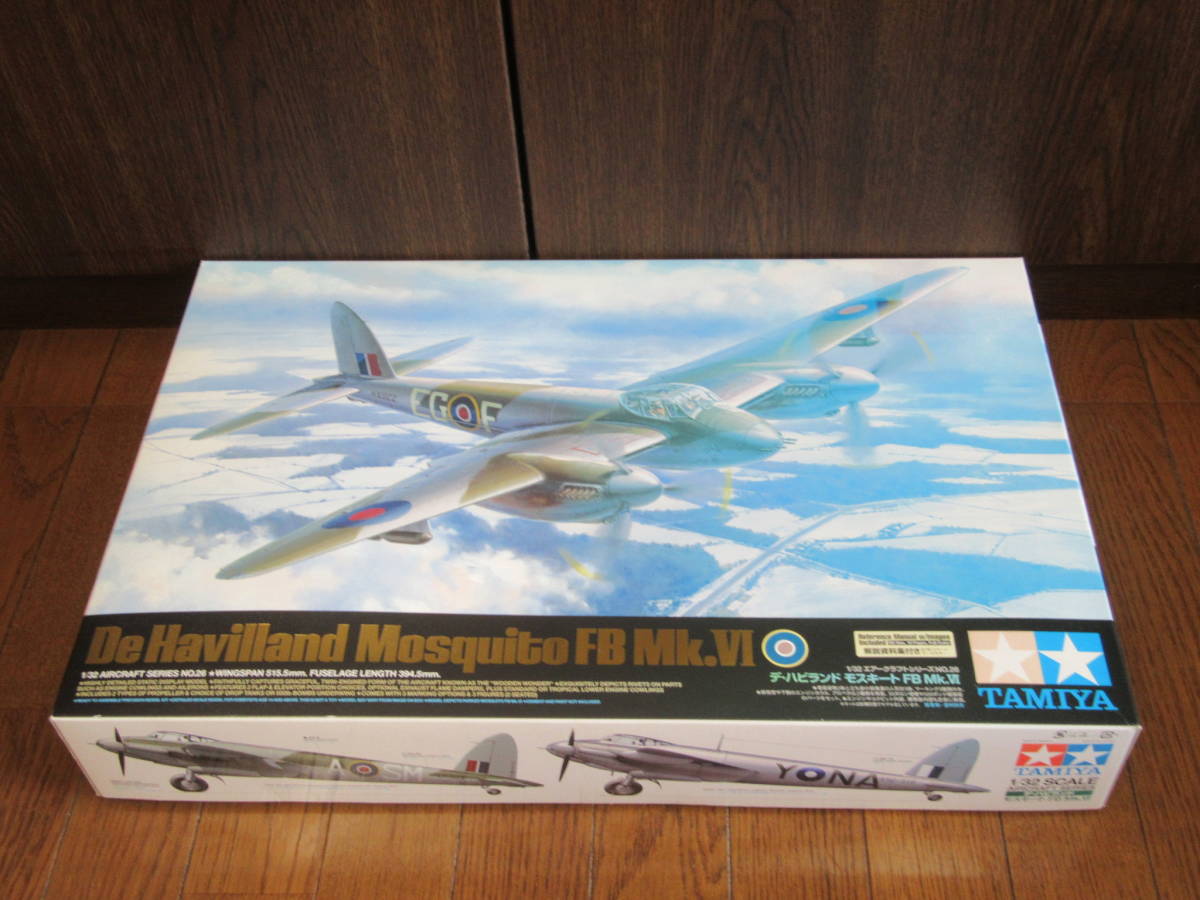

完成品♪タミヤ 1/24 ホンダ NSX ホワイトパール塗装

¥12,900